Mhedzisiro yemicroporous ceramic atomizing musimbotipamagetsi smog

1. Porosity vs. simba

Kupokana kwekutanga kwekeramics: kuderedzwa kwesimba kuchaita kuti ceramics idonhe hupfu, pakupera kwekudonha, gungano rinowanzoita kupatsanurwa, zvichikonzera kuderera kwegoho.

2. Pore size vs. mafuta conductivity

Iyo pore saizi yemicroporous ceramicshaina kuenzana mu microstructure uye haina yenguva dzose geometry.Iyo pore size yakakura kana diki.Iyo aperture ye microporous ceramics kazhinji inoreva kugoverwa kwepakati, mune inoenderera inoyerera chiteshi, iyo diki aperture kune huwandu hwemafuta inoita basa rekuita, huwandu hwemafuta hunoenzana neskweya yeaperture, yakakura iyo aperture, iyo nekukurumidza mafuta.

3. Aperture vs

Pamusoro pekukanganisa chiyero chekufambisa kwemafuta, aperture chimwe chiratidzo chakakosha kuravira.Kana atomizing, kana mafuta echiutsi ari chimedu chihombe cheatomi, kuyerera kweutsi kunenge kwakakora, uye madonhwe anoumbwa mushure mekugwinya akakura, ane kuravira kwakasimba uye kunonakidza.Iyo buri diki, iyo inoyerera yakatsetseka inoyerera inoumbwa nemafuta madonhwe atomization, iyo aerosol particles akagadzirwa zvakanaka, zviri nani kuparadzira mhedzisiro, yunifomu, kuravira kwakapfava.Naizvozvo, iyo diki yeoiri inotungamira aperture, zviri nani.

Kuongororwa kwemarwadzo ekurwadziwa kwemicroporous ceramic atomizing musimboti

Iyo oiri conduction chivakwa uye kusimba kweceramics hazvigone kuverengerwa, saka yakakura aperture inodiwa kuti uwane yakakwana yekuitisa oiri kugona.Aperture yakakura ichaita kuti aperture yeceramic ideredze;Kuravira kwakanaka kweceramic atomizing musimboti kunoda diki rakakwana aperture;Ceramic simba, conduction yemafuta, kuravira zvinodiwa zvekuvhura zvakapesana chaizvo.Ceramics mune izvi zvitatu zvekuita hazvigone kutarisa kune ese ari maviri, zvinopokana.Asi musimboti weceramic atomization core, kusanganisira iyo yakakosha kukwikwidza kwe-e-fodya ndiko kuravira, iko kuita kunoda kuvimbiswa kutanga.Naizvozvo, saizi yepore idiki zvakakwana kupa mafuta akakwana.

1. Saizi yakanaka yepore uye yakakwirira porosity:

Nano ceramic zvinhu zvekugadzira tekinoroji, kudzora saizi yechidimbu uye kusungirirwa kweceramic pore, tora yakanaka pore chimiro uye yakadzika pore saizi kugovera, dzivirira kurasikirwa kwesimba kunokonzerwa nemapores makuru.Gadzirisa kupararira kufanana kweceramic poda, wedzera iyo pore-yekugadzira dosi, uye uwane yakakwirira porosity.

2. Chiedza chemicroporous ceramics:

Shandura iyo fomula yezvinyorwa, gadzirisa simba remukati reiyo microporous ceramic zvinhu, kunyatso dhizaini uye kudzora tembiricha yekupisa, kuwana yakanaka sintering degree, kuwana chiyero pakati peporosity nesimba.Yakanyatso dhizaini dhizaini inowana chiyero pakati pesimba, porosity uye aperture, kuti uwane yakanakira oiri conduction uye kuravira maitiro.

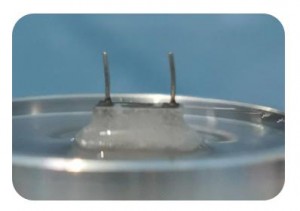

3. Imwe pfungwa inorwadza yeceramic core ndeye evaporation ye nicotine uye essence mumafuta efodya.Inoda nzvimbo yakagadzikana yekushisa, uye kugoverwa kwekushisa hakuna kufanana.Kuti uteedzere kuravira kwekupedzisira, kupisa waya kugadziridzwa kunodiwa kuti iwedzere kunaka kugadzirisa uye kugadzirisa, saka ikozvino kusimudzira maitiro eiyo microporous ceramic atomization musimboti ndeyekuita yakagadziridzwa simbi pane iyo ceramic substrate.Kune nzira dzakawanda dzesimbi dzeceramic nzvimbo, uye imwe yeanonyanya kushandiswa matekinoroji parizvino e-fodya ndeyekudhinda firimu, yakafanana nePCB brashi solder paste.Iyi maitiro haangoitirwe chete panzvimbo dzakati sandara, asiwo pane 3D nzvimbo.

Nguva yekutumira: Jul-19-2022